-

Industry Solutions

-

Tooling Design & Manufacturing

Tooling Design & Manufacturing

-

Product Applications

-

Social Responsibility

-

About Us

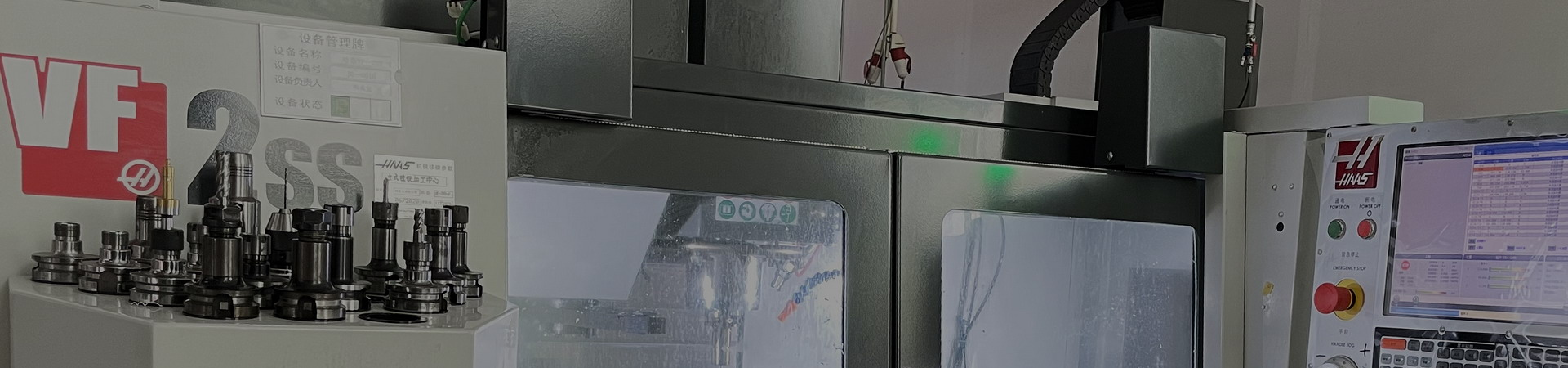

Tooling Design & Manufacturing

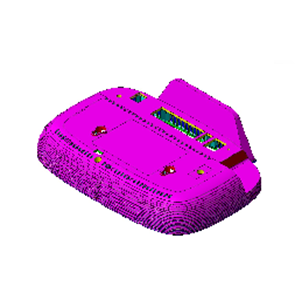

With a blend of technology and specialized tooling equipment, we create necessary tools and select appropriate materials for specific applications ensures that the finished product meets the necessary standards for strength, durability, and aesthetics.

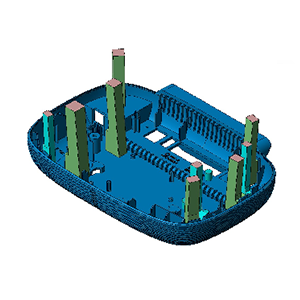

Mold Manufacturing Capacity

Technicians settle applied manufacturing technology and technological standard uniformly,formulated a system with specific category,comprehensive coverage, uniform database to form standards for mold manufacturing process,technology and technological parameter.

In our technology standard system, there are including material and injection molding process,mold steel and manufacturing technology,mold design and drawing,CNC program and manufacturing,EDM electrode drawing and programing,mold assembly,mold trial package ,other manufacturing technology and production management and so on.

Using this system in production, will make our technicians get comprehensive technology guidance,reducing continual study process and make sure the correct standard technology parameters are under monitored during manufacturing to shorten mold building leadtime,reducing cost and improving mold quality to meet the demand of products customization from each customer.

To implement this standard system,Ricen factory immobilize the workflow for relative key positions of mold design and manufacturing departments,building relevant inspection list and monitoring mechanism to assure the production stability and accelerate the improvement of production efficiency.

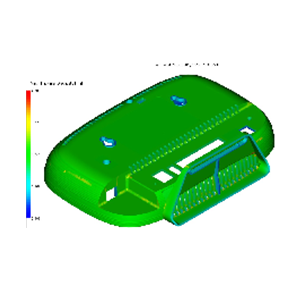

Injection Molding Process

● 2k mold ● Overmoulding ● Insert mold ● Gas-assisted mold ● IML mold ● Unscrewing mold

Mold Size

● Max length: 1.8m ● Max weight: 15T

Leadtime

● Small- sized molds: 3-4 wks ● Middle-sized molds: 5-6 wks ● Larger molds: 7-9 wks

Production Capacity

● Monthly: 50 sets

WayHone Technology

-

Chairman: Simon Liu

Tel: 0755-23310960

Fax: 0755-29973775

E-mail: sales@wayhone.com -

E-mail: simon.liu@wayhone.com

Copyright 2024 WayHone all rights reserved.