-

Industry Solutions

-

Tooling Design & Manufacturing

Tooling Design & Manufacturing

-

Product Applications

-

Social Responsibility

-

About Us

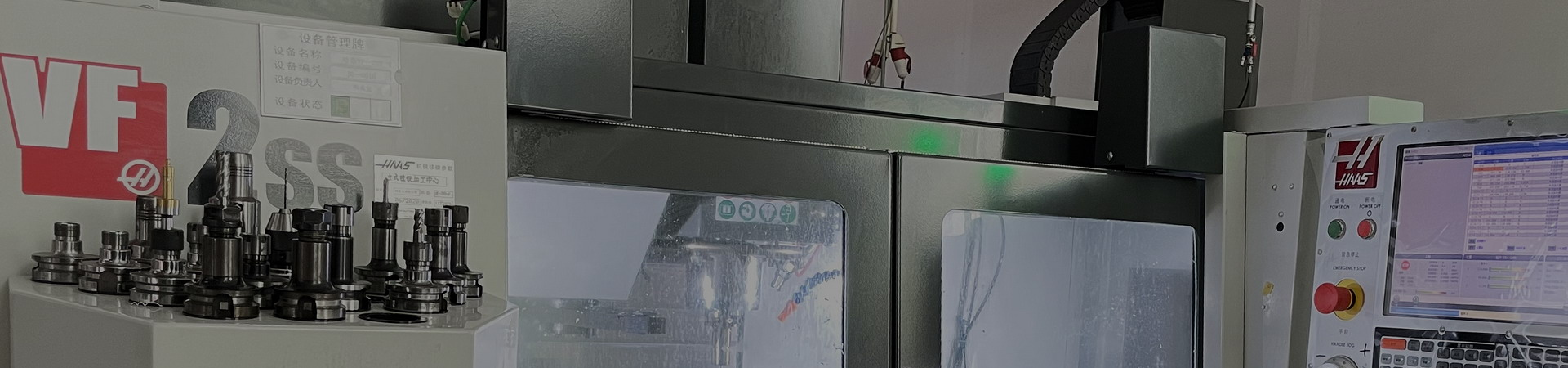

Tooling Design & Manufacturing

With a blend of technology and specialized tooling equipment, we create necessary tools and select appropriate materials for specific applications ensures that the finished product meets the necessary standards for strength, durability, and aesthetics.

Design For Manufacturing

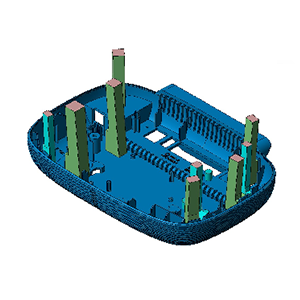

DFM is an important content in mold design, its purpose is to be able to consider manufacturing-related problems in the early stage of the design, in order to reduce and find design defects as early as possible, shorten the mold development cycle, reduce costs.

In DFM review, engineers need to consider the manufacturing dependencies and manufacturing constraints in the mold manufacturing process. These constraints are mainly the structural constraints of the mold: generally including product material, shrinkage rate, mold cavity number, gate form and position, parting line, slider, draft angle analysis, wall thickness analysis, cooling water distribution, ejection mechanism type and position, put forward effective suggestions to optimize product structure to meet the mass production of the mold.

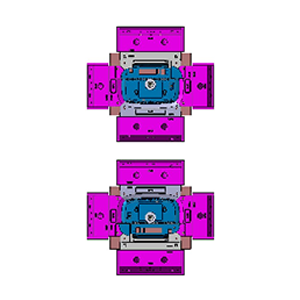

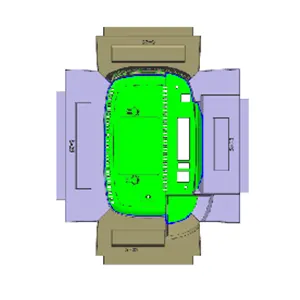

Mold layout

● Confirm the distance between the parts ● Confirm the direction and position of part ● Confirm ejectors,gate,cooling system design

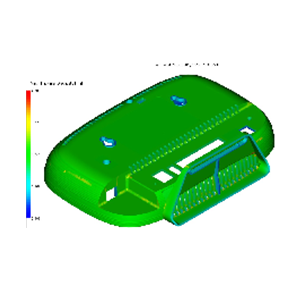

Draft angle

● Check if draft angle will be ok for release ● Check if draft angles will affect surface ● Check if draft angles will impact on size and strength of wall thickness

Lifter position

● Confirm the position and size of lifters ● Check if there will be interference between lifters and angles ● Check the risk of sticking issue

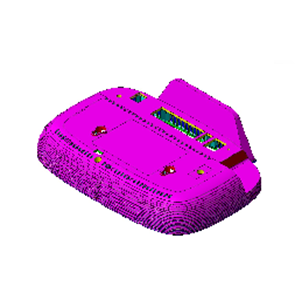

Analysis for wall thickness

● Analyse the position of uneven wall thickness ● Check the influence of uneven wall thickness on the appearance defects of the product

Slider position

● Confirm the position and size of sliders ● Check if sliders will impact on visible surfaces ● Check the risks of sticking issue

WayHone Technology

-

Chairman: Simon Liu

Tel: 0755-23310960

Fax: 0755-29973775

E-mail: sales@wayhone.com -

E-mail: simon.liu@wayhone.com

Copyright 2024 WayHone all rights reserved.