-

Industry Solutions

-

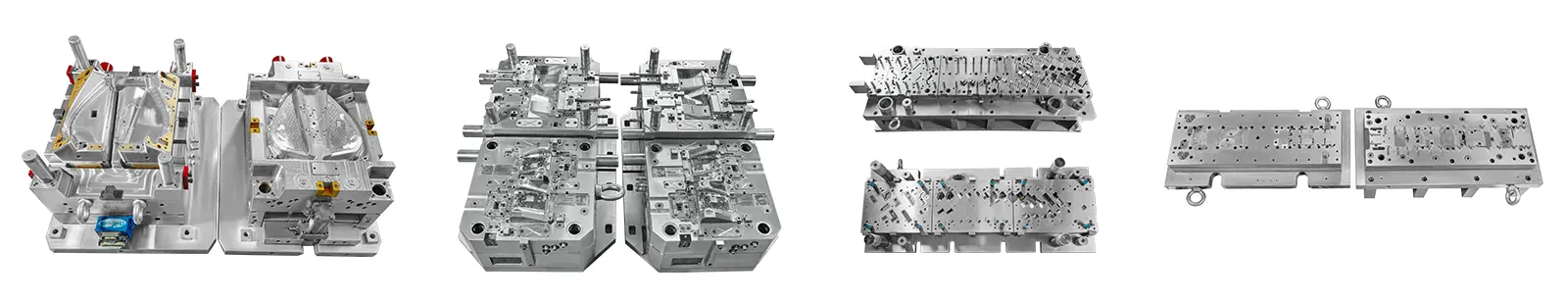

Tooling Design & Manufacturing

Tooling Design & Manufacturing

-

Product Applications

-

Social Responsibility

-

About Us

Tooling Design & Manufacturing

With a blend of technology and specialized tooling equipment, we create necessary tools and select appropriate materials for specific applications ensures that the finished product meets the necessary standards for strength, durability, and aesthetics.

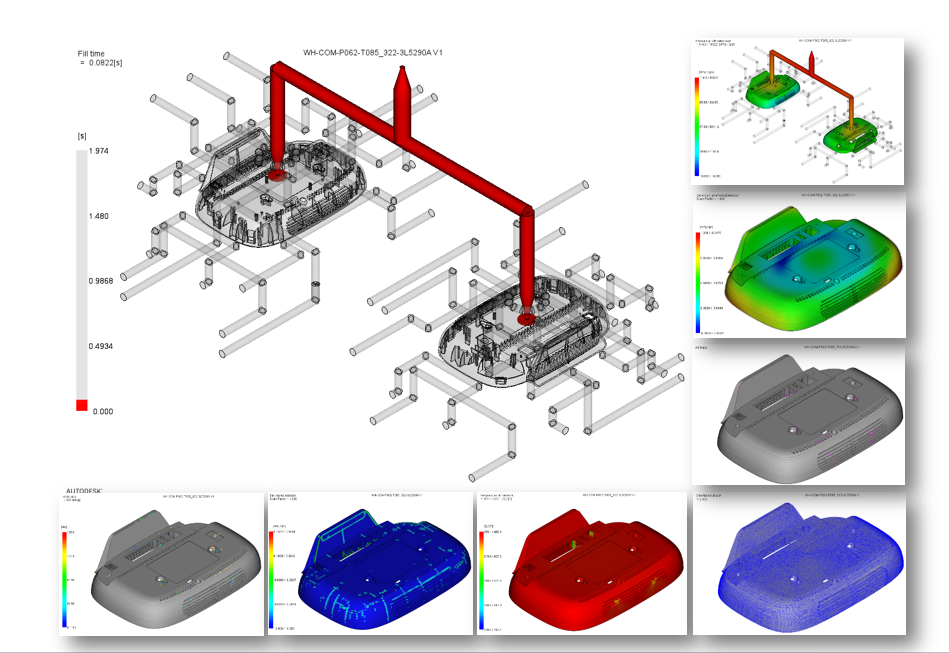

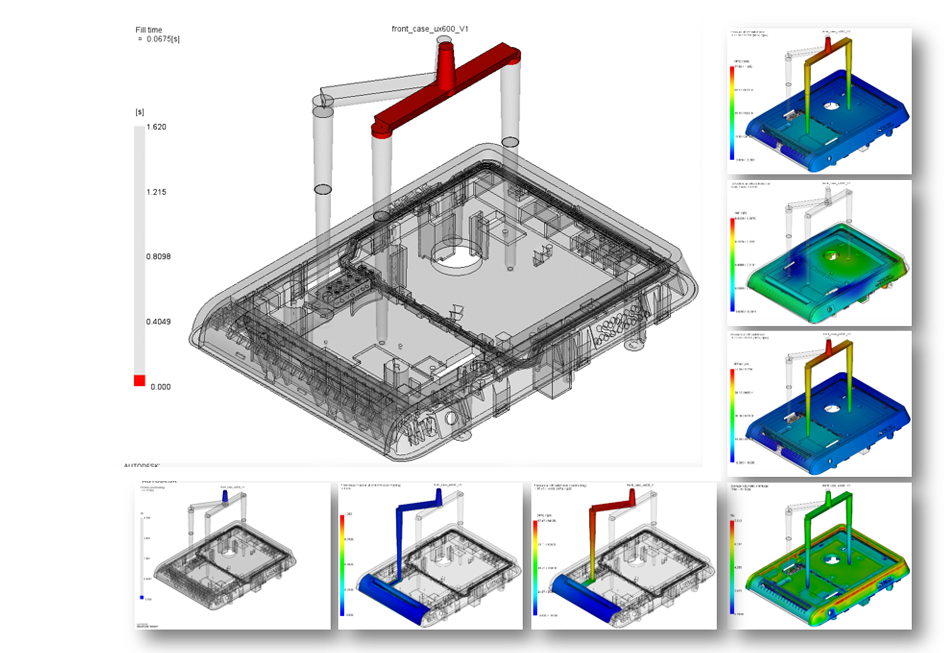

Engineering Capabilities

We can find some possible defects during mold injection by software to make the mold design optimized and part innovated. This will help reduce the cost for physical model and lower the risks during manufacturing.

Our core value is to provide customer solutions on part optimization, material choice,gate position/size,cooling/deformation etc.

√ Estimation and optimization on part defects

√ Optimizations for mold design and injection

√ Estimation and optimization on part size

Mould Design

We have a team of more than 20 engineers who are familiar with domestic and international mold standards. We are familiar with the characteristics of mold structures, mold steel, resin. Our experience can help engineers to understand the realization of product ideas.

CNC Program

Our CNC programmers will analyse on the geometric modeling,size,accuracy and material of part contour and steels

Confirm the machining technology.

1. The key point of spare part manufacturing (such as fixture usage,location point)

2. Processing way (such as feed way,cutter-setting and change point)

3. Technological parameter (feed rate, spindle speed,cutting rate and depth etc)

Write program for processing steps per confirmed manufacturing parameter

WayHone Technology

-

Chairman: Simon Liu

Tel: 0755-23310960

Fax: 0755-29973775

E-mail: sales@wayhone.com -

E-mail: simon.liu@wayhone.com

Copyright 2024 WayHone all rights reserved.